Tabs Explanation

Summary

A Cell represents either a machine or a cell (two or more machines acting like one) within a Department. You can override the default settings for the Company, Facility, and Department for a specific cell or machine.

Cell and machine can be used interchangeably depending on your configuration.

Features

- Enabling line configurations gives the user the ability to define how a cell or line is configured

- Collection of data and calculation of OEE is centered around the Cell record

- Cells can be configured to auto-start and auto-stop based on the shift schedule

- Cells contain the mapping for incoming machine events

Content

General Tab

Cycle Time Tab

Tag Mapping Tab

Metrics Tab

Attachments

Settings

Custom Fields

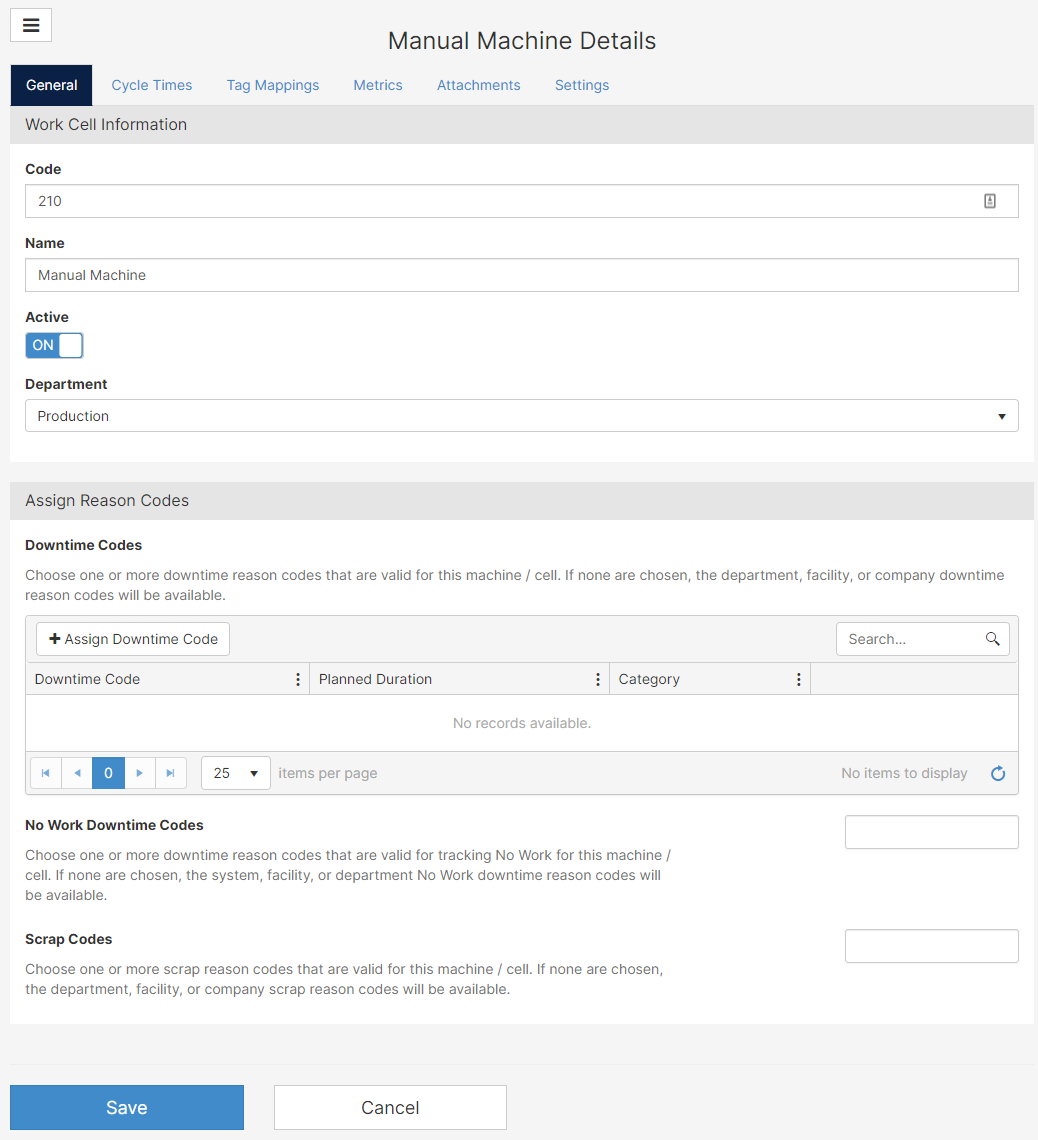

General Tab

Work Cell Information

- Code: Unique code for this machine, line, cell, or workstation

- Name: Name of the machine, line, cell, or workstation

- Active: Set the machine active or inactive, see notes below on the effect of setting a cell inactive

- Department: Department for this machine

Assign Reason Codes

- Downtime Codes: Downtime codes that are valid only for this machine. These codes will override the codes provided by the department or facility.

- No Work Downtime Code: assign No Work Codes to this Cell/Machine. All other codes will be ignored.

- Scrap Codes: Scrap codes that are valid only for this machine. These codes will override the codes provided by the department or facility

Active/Inactive Switch

If a cell, group, or device is marked inactive, it will not show up in the drop-down options for the following:

- Create Production Day

- Report Scrap

- Report Downtime

- User Assigned Work Cell

- Scoreboard

Inactive cells can still be selected for historical purposes: dashboard filters, production history grid filters, edit events, etc. Inactive cells, groups, or devices display in the drop-down options in grey, italicized text with the label "(inactive)".

If there is a currently running production record for this cell, it will continue until the end of the current shift and won't restart.

Cycle Times Tab

This is where the cycle times are defined for this machine or cell.

Default Cell Cycle Time

- Planned Cycle Time defines the cycle time for the machine regardless of what parts are running on it. This is the cycle time the facility is able to run the machine at.

- Ideal Cycle Time assigns an ideal condition the machine can run at. For example, the maximum speed of the machine is 300 parts every minute.

- Cycle Time Unit is the metric you would assign to your cycle time. There are a few options like minutes per part, parts per hour, and cycles per second.

- Scale by Headcount multiplies the parts by the number of resources you select. Increasing the number of workers will increase the throughput of that line.

- For example, if the cycle time is 10 parts per hour with 1 person and the cycle time is 20 parts per minute with 2 people, turning on Scale by Headcount allows you to set a single cycle time that increases with the headcount.

- Parts per Cycle is the number of parts each event in a cycle will display. This setting is used when you have molds or processes that produce more than one part per cycle. For example, in injection molding, you may have 2 cavities and 2 bottles are produced with each cycle.

Operation Cycle Times

- Operation Cycle Times define operation-specific cycle times for when different parts run at different rates on the machine.

- When you add an operation cycle time you must choose a part number from the drop-down. Then the settings are the same as the default cycle time above.

For detailed information on cycle times and the cycle time hierarchy, check out this video.

Tag Mappings

Connection Heartbeat

- Tag Name: name of the tag where the heartbeat is located

- Timeout: after a minimum of 120 seconds of inactivity, an alert would be sent

Tag Mappings

Tag mappings are user-defined labels for data or events. For example, a quantity event coming from a PLC will trigger a tag with the number of pieces produced by the machine. To learn more, click here.

Metrics Tab

The metrics tab for facilities is functionally the same as the metrics tab on the Company record.

Metrics use the following hierarchy:

- Cell

- Department

- Facility

- Company

Attachments

List of PDF files attached to the selected machine.

- Upload Files: select the files you wish to upload.

- Choose Existing: list of files you can choose from to upload to the machine selected.

Settings Tab

On this tab, you can control the more advanced settings for machines and cells.

Short Stop Settings

Short stops or downtime detection allow Mingo to detect when a machine is down and ask for a reason why. This is typically used when the machine cannot tell Mingo why it is down, like breaks, lunches, etc.

- Threshold Type: controls the type of shortstop that would be used

- None: shortstop detection is turned off

- % Of Cycle Time: the shortstop is triggered based on a percentage of the cycle time. If you have many different parts that can run on a machine with very different cycle times this is a good option to choose.

- Duration in Minutes: short stops are detected after a certain number of minutes of inactivity from the machine.

- Short Stop Threshold: The duration in minutes or percentage of cycle time to mark the machine as down and start tracking downtime.

- Short Stop Prompt Threshold: The duration in minutes after a machine is down to prompt the operator for the reason why the machine is down.

- For example, you may want to start tracking downtime if the machine has not made a part in 30 seconds, but you don't want to prompt the operator for why until it has been down for more than 5 minutes.

- Short Stop Reason: The reason code to use for the shortstop

Start/Stop Settings

You can configure the production records to start automatically at the beginning of a shift and stop automatically at the end of a shift. This section controls those settings.

- Calendar: Choose the shift calendar for this cell to override the company, facility, or department default.

- Auto Start: If enabled, the cell will automatically start based on the calendar and shift schedule assigned.

- Auto Stop: If enabled, the cell will automatically stop based on the calendar and shift schedule assigned.

- Change Over Reason: If selected, a downtime will automatically start with this reason code when you change over to a new production run.

- Change to No Work at Shift Change: When enable and the quantity was met at the end of the shift, the next shift will start with the No Work Part.

Other Settings

- Cost/Hour: Hourly cost to operate cell/machine. This value is used to calculate the Performance Cost and Unplanned Downtime.

- Ignore Subsequent Downtime: If enabled, when a group of downtime reasons is received from a machine only the first downtime will be used. Currently, the first downtime received depends on what the machine sends to Mingo.

- Ignore Performance: If enabled, performance for the cell is 100% regardless of actual cycle time. This option can be overridden by the part's setting, or if an operation cycle time is in use for this part.

- Ignore Quality: If enabled, quality for the cell is 100% regardless of the actual scrap entered. This option can override by the part's setting.

- Post Production Scrap Reporting: If enabled, a negative good quantity will be recorded along with the scrap quantity to offset any good quantity that should have been recorded as scrap. Essentially, you are removing a good quantity and adding a scrap quantity after the production run was completed.

For more information about Post Production Scrap Reporting, please click here

- End of Run Report: allows the operator to audit the quantity, scrap, and downtime to corroborate the end of the production run.

- External ID: An external ID used to reference the cell in external systems. This is optional and only used for reference.

- Process Data Metrics: choose one or more data metrics that are valid for this machine. Only selected metrics will display for the operator.

Video

Custom Fields

Any custom fields you added on a machine level will be shown here.