When multiple machines work as one

To learn more about Cell/Machines, please visit the following Article Cell/Machine Overview![]()

Overview

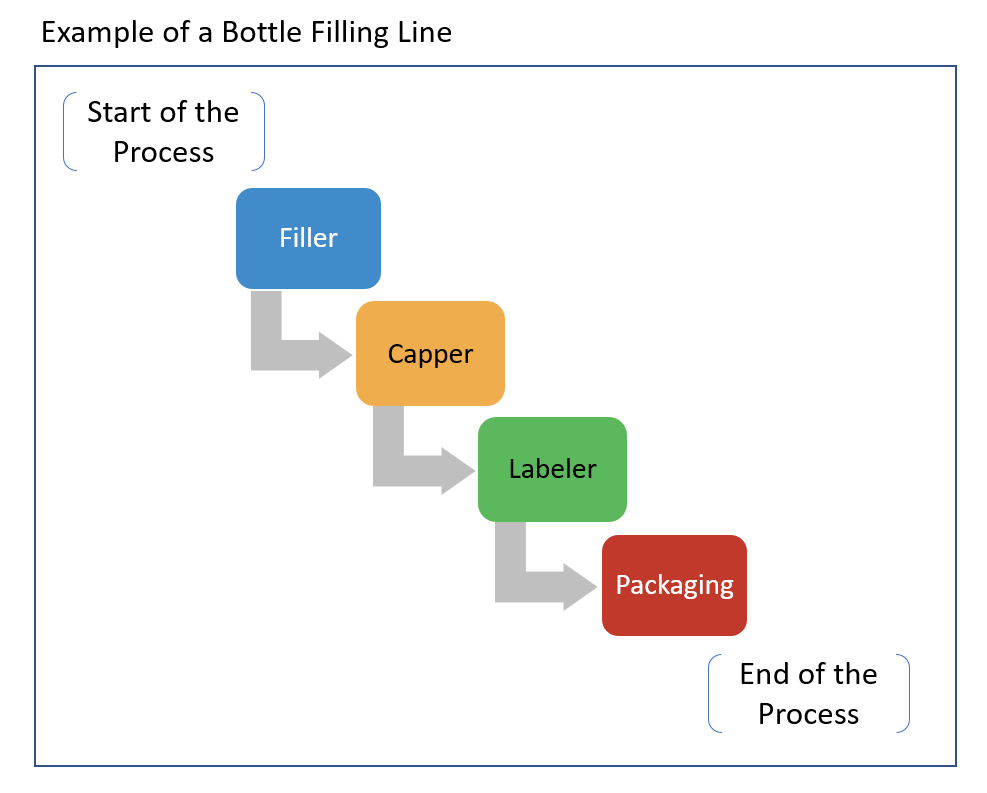

In manufacturing, it is common for multiple machines to work as a unit. For example, if you are filling a bottle with fluids, placing a cap, labeling the bottle, and packaging it. You might want to group these four machines into a bottle-filling Cell or Line. Mingo calls this process Machine Layout.

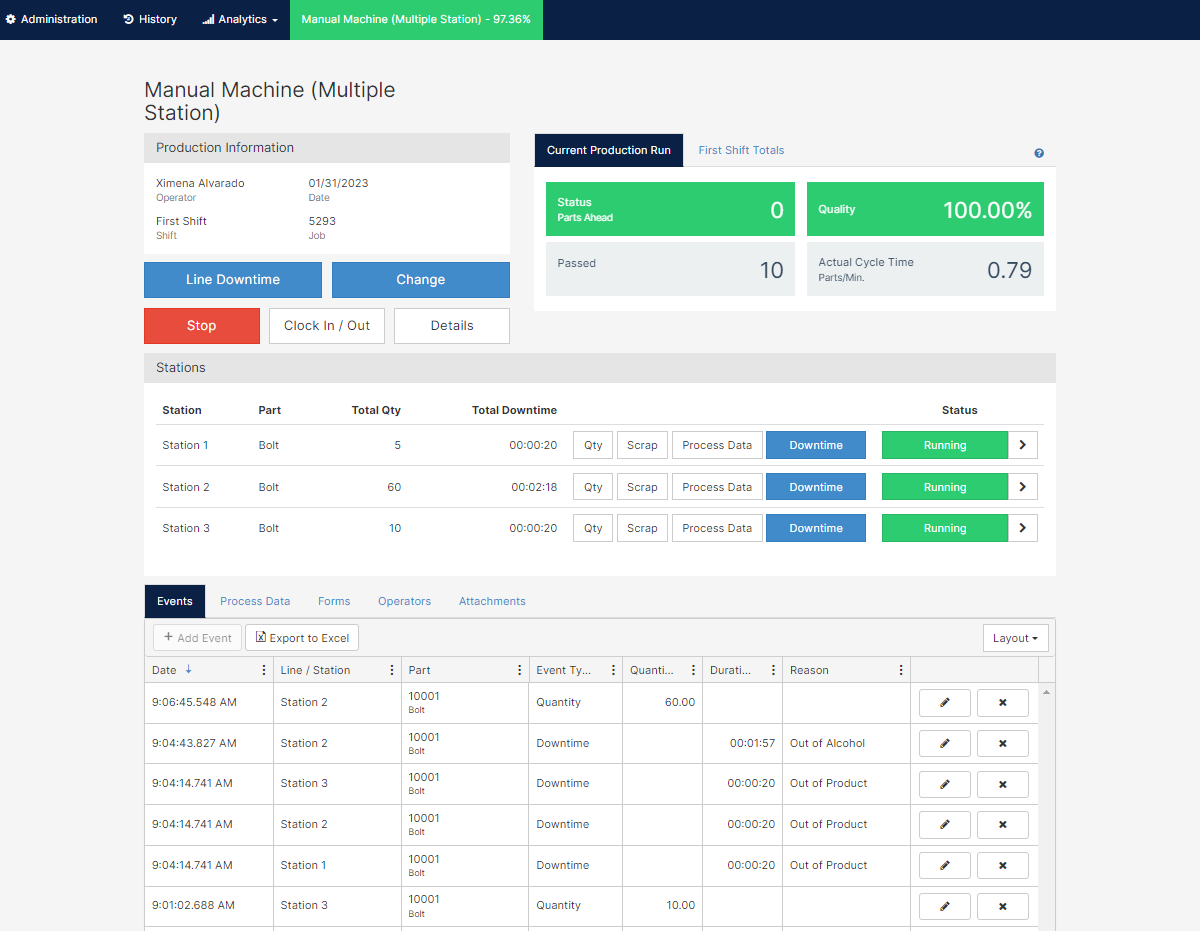

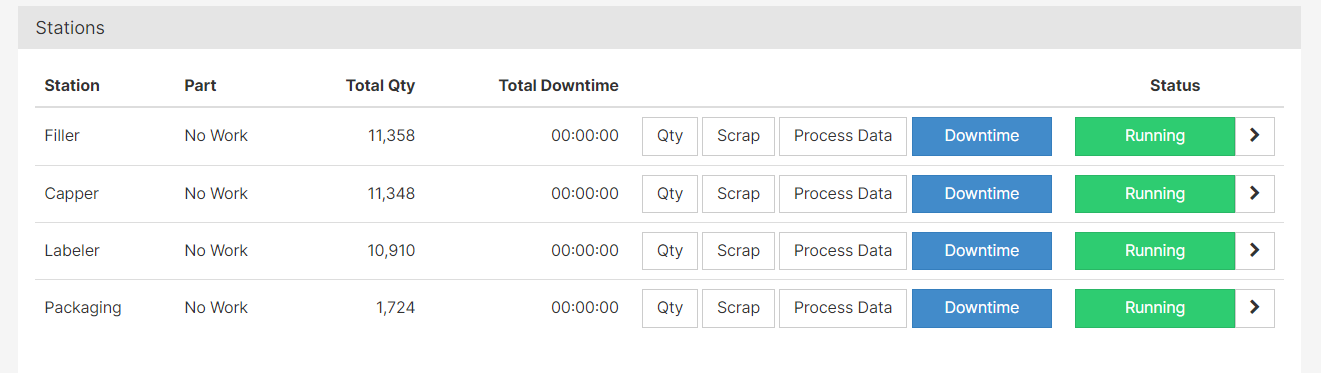

Screen Overview:

The Total Good Quantity and Total Scrap for a Line comes from the last Station.

How to create a Machine Layout

To create machine layouts, you need the proper license and permission. Please contact a Mingo representative for support.

- Go to the Administration Tab, and select Cells/Machine

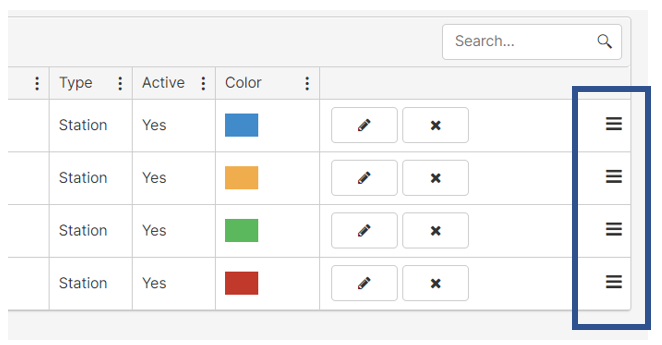

- After creating or selecting the line by clicking Layout, assign the right stations for the Line.

Stations can be added by clicking Add Station.

Stations can be added by clicking Add Station. - The order for the stations can be changed by clicking and dragging each station to the desired position using the triple dashes. The last station has the tag "Final Operation". This tag is automatically assigned by Mingo.

- Cycle time, downtime codes, and more can be allocated to each station. [Click] the pencil icon to perform this change.

- On the Operator Screen, you would be able to see: the name of the station, Part Number, Total Qty per station, Work Order Completion %, and Total Downtime.

Downtime Events in Layouts

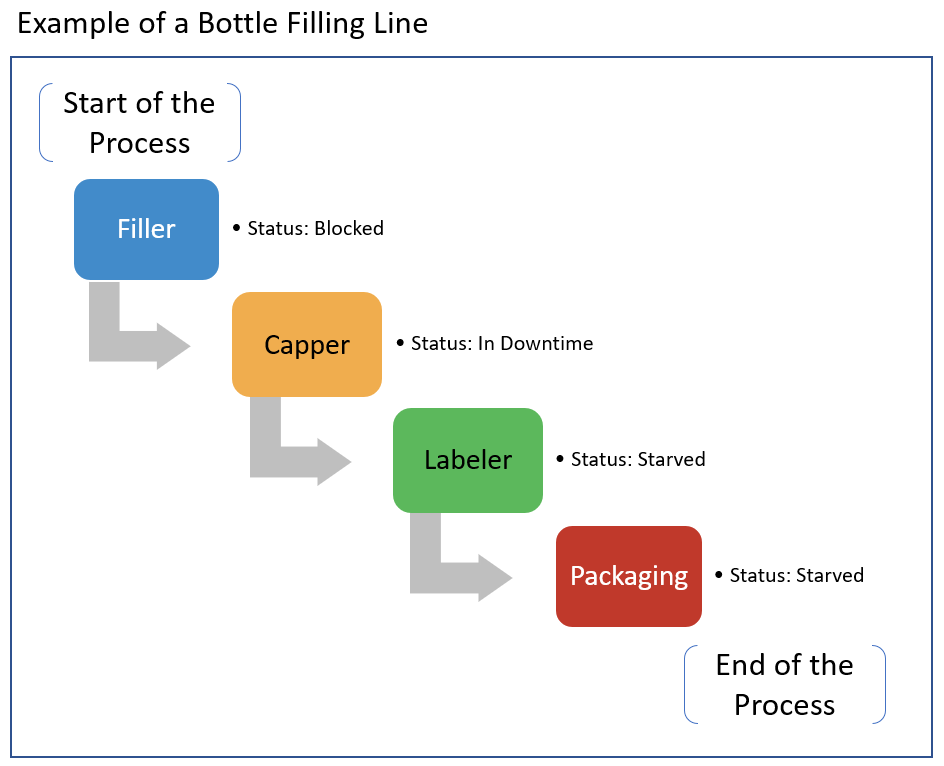

When a machine in the layout is in downtime, the other machines are either starved of production or blocked from performing their function.

Difference between statuses: Starved and Blocked

A station is considered starved when a station before them is in downtime. On the other hand, a station is blocked when a station after them is in downtime. For example, if the capper is in downtime, the other stations would have the following status: