Set durations for planned downtimes

Overview

Downtime Duration allows you to set a pre-established duration for your downtime codes. When the set duration goes over the allocated time, the system will automatically change the downtime type to "Unplanned". This switch will show the amount of time you went over the planned downtime duration.

Video

Function

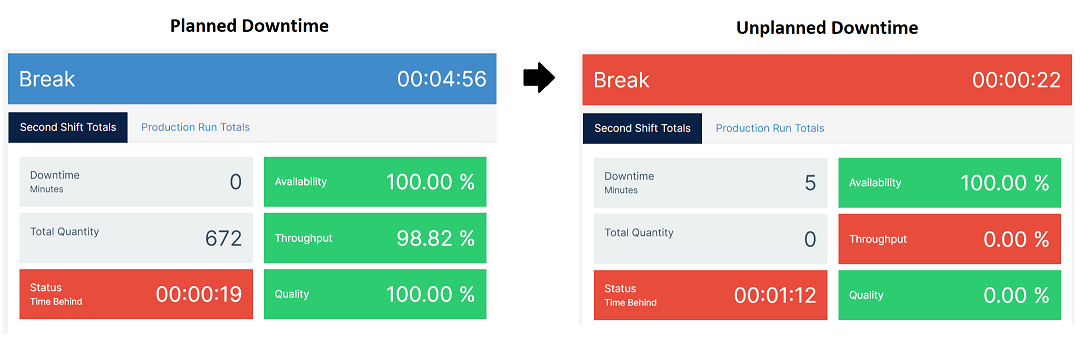

From Planned Downtime to Unplanned Downtime

On the top of the screen, the planned downtime will begin the countdown from the specified duration. When the timer goes over the allocated time, the downtime event will change to unplanned, and the timer will start counting up.

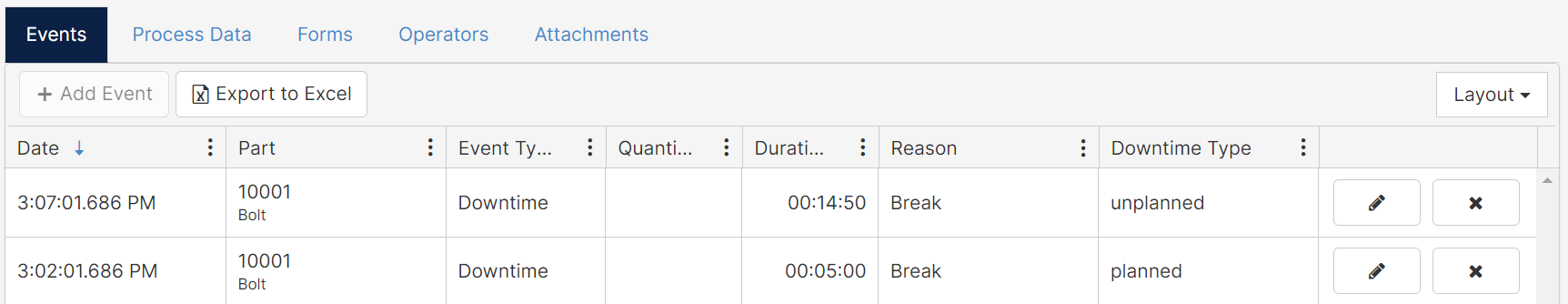

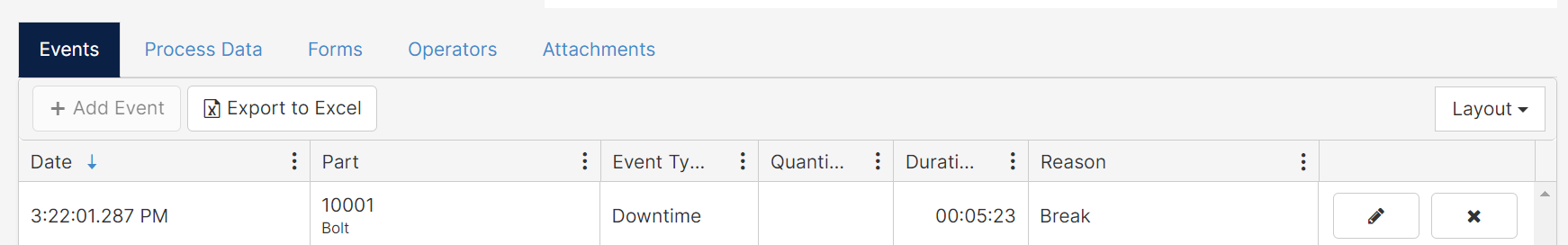

On the event log, you can see the distinction between the two downtime events.

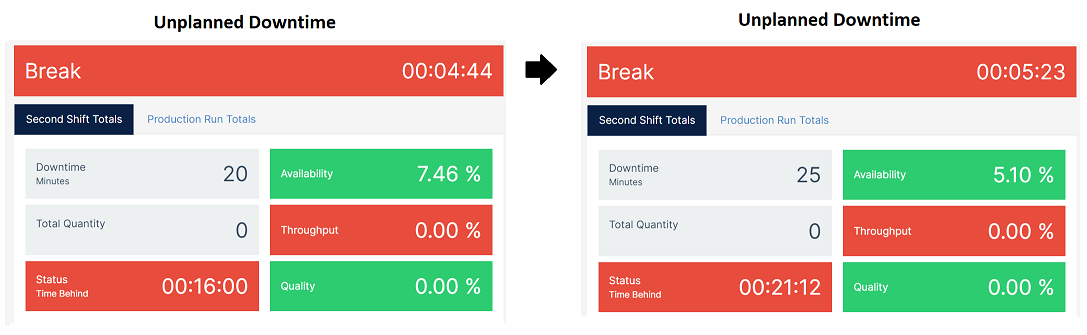

From Unplanned Downtime to Unplanned Downtime

You can set a planned duration threshold on an unplanned downtime. After the planned duration is met, the timer will start counting up. For example, the downtime "Break" had a planned duration threshold of 5 minutes. After the threshold elapsed, the second production run shows the counter increasing.

Instead of creating two separate events, the event log will show the overall time for the downtime event.

You can have similar functionality with a pre-scheduled downtime event using the Scheduled Downtime feature.

Add a Planned Duration to a Downtime Code

A downtime code is required before setting a planned duration.

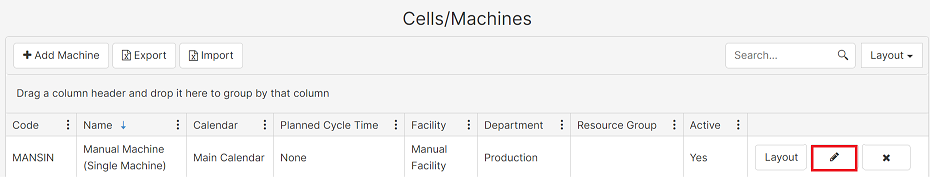

- On the Administration Tab, click on Cells/Machines.

- To add a planned downtime duration, edit the machine.

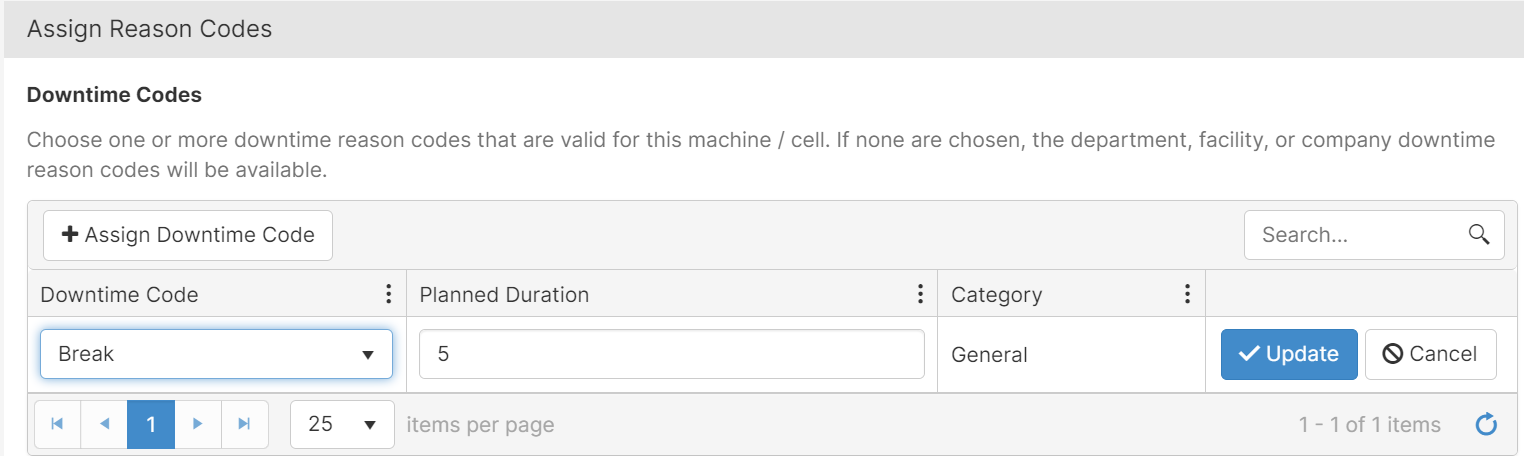

- On the General Tab for the machine, Assign the Reason Codes.

- Downtime Code: Downtime code previously created in Master Data. This is required.

- Planned Duration: How long the downtime is expected to last in minutes. This is required. The Planned Duration can be left at "0" to forgo this functionality. If the duration is set to 0, the timer will count up from the onset and the event will never change from planned to unplanned.

- You must click Update to save the changes. If you click Save without updating your changes, then the settings will not save.

Production Run

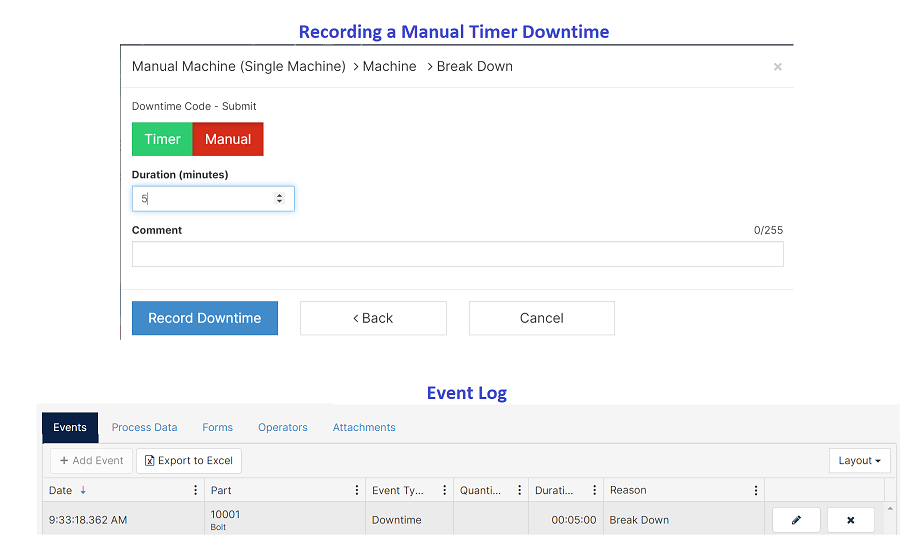

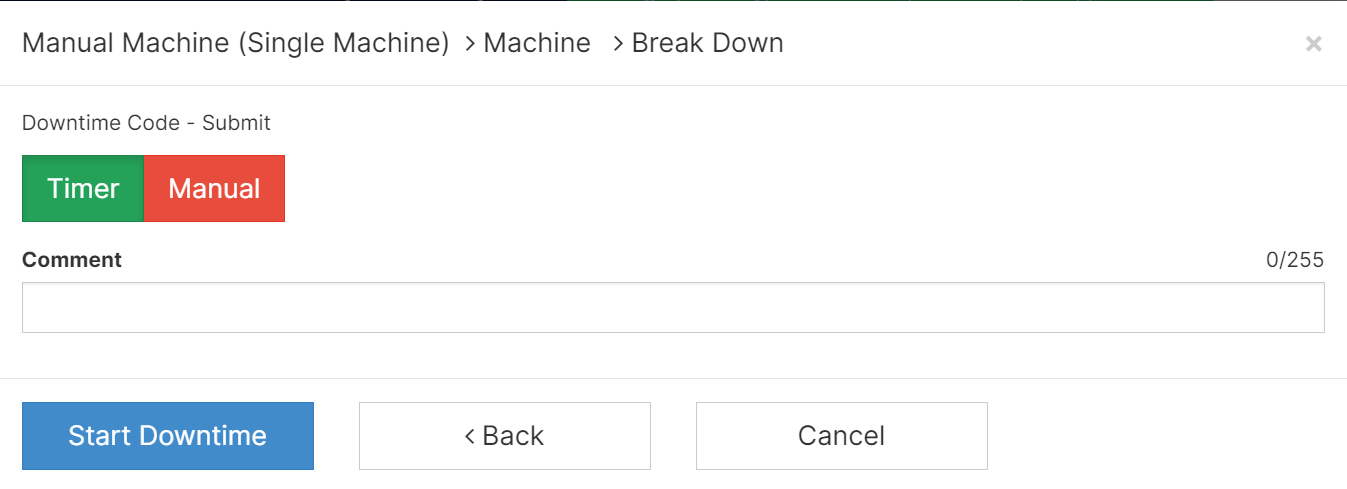

When an operator selects a downtime, they may choose between Timer or Manual.

- If the Timer option is selected, the predetermined duration will begin. When the value of the duration is zero, the timer will begin counting up.

- If the Manual option is selected, the input will override the timer. The operator must enter a value for the duration that is 1 or greater. When Record Downtime is selected, the event log will reflect a downtime event with this manual duration.