Default Cycle Times and Operation Cycle Times

Please click here for definitions, formulas, and examples of how cycle times are calculated in Mingo.

Default Cycle Times

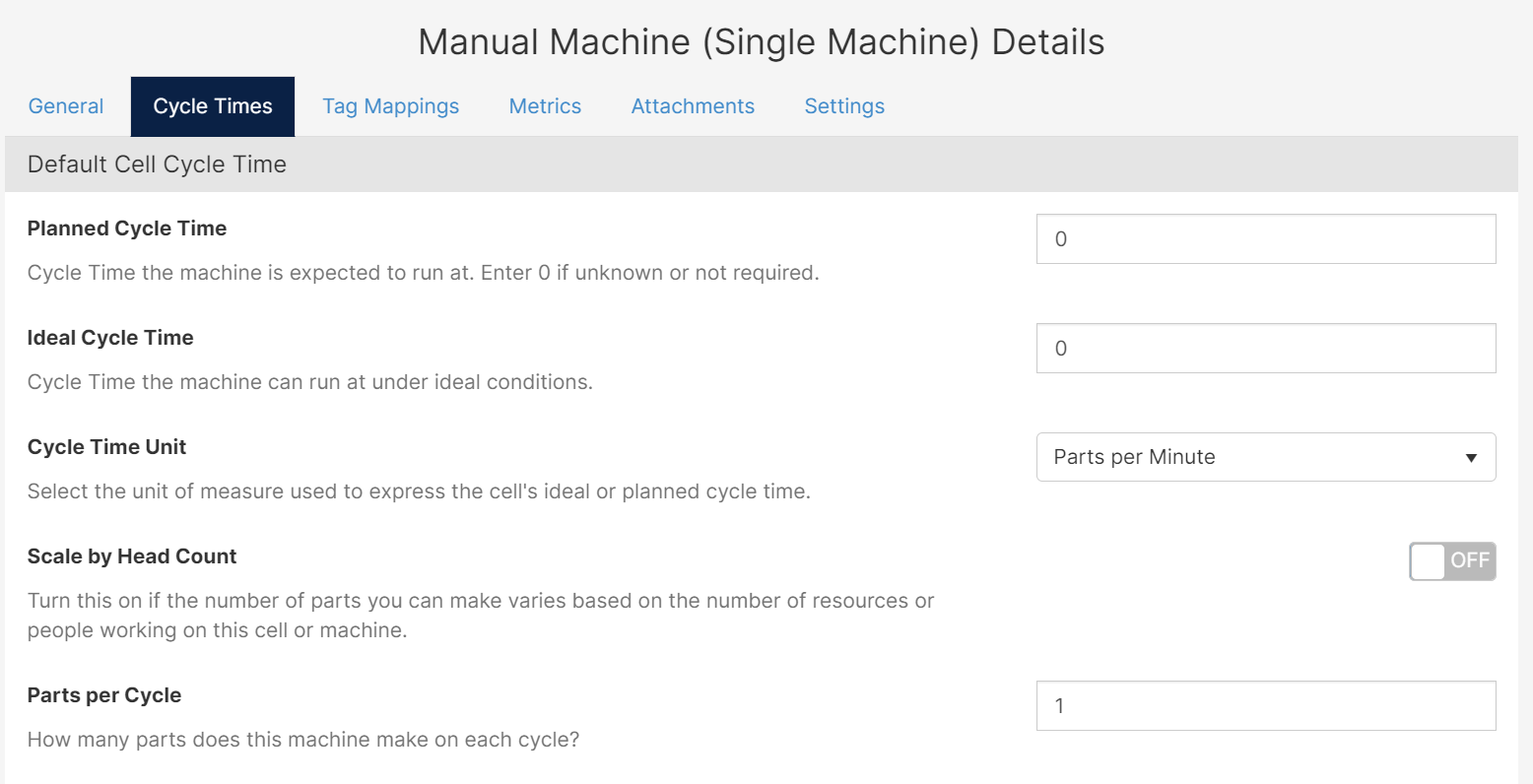

Cells/Machine

This default cycle time will be assigned to the machine. Any part that does not have a cycle time will be given this cycle time.

- On the Administration Tab, click on Cells/Machines on the Hierarchy.

- Add a Machine or edit the machine you need.

- Select the Cycle Time Tab.

- Fill in the Default Cell Cycle Time information.

- Save your changes.

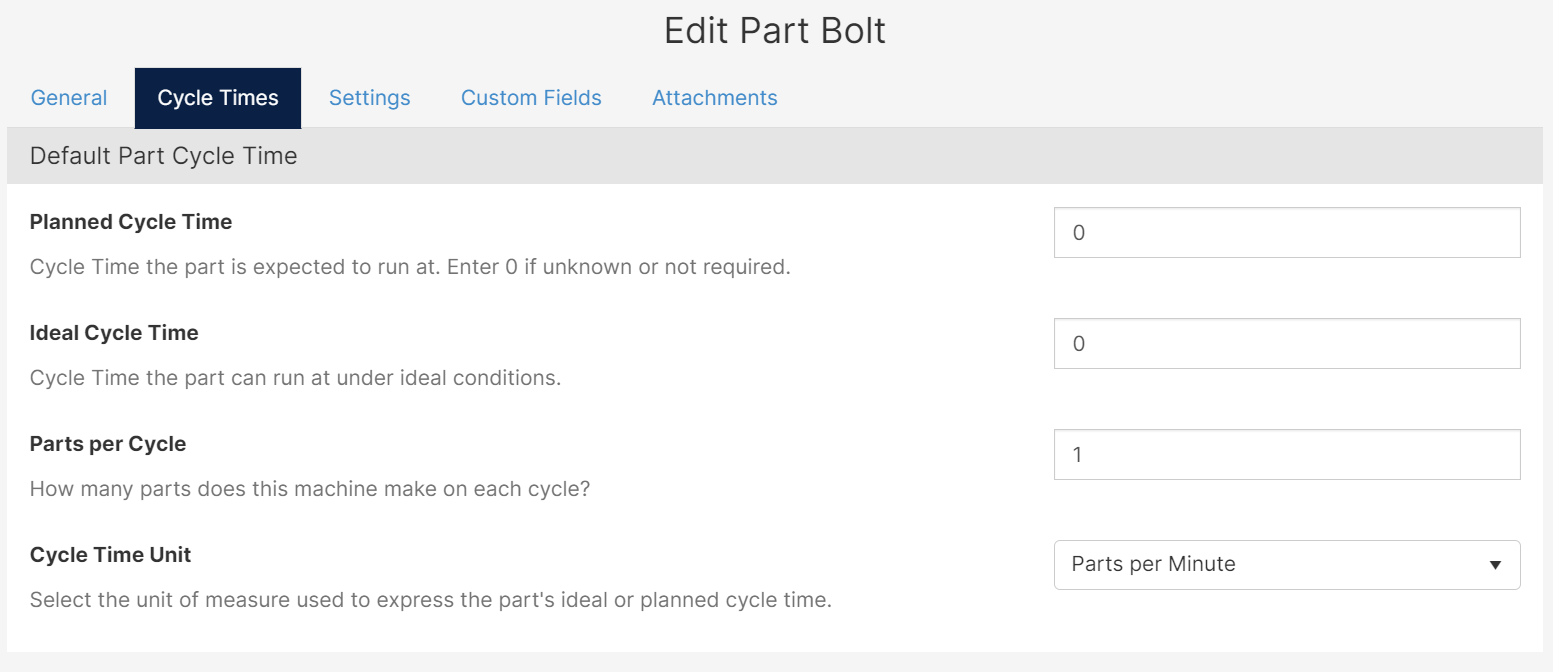

Parts

Regardless of the machine, the default cycle time for the part will be used if no operation cycle time is defined.

- On the Administration Tab, select Parts on Master Data.

- Add a Part or edit the part you need.

- Select the Cycle Time Tab.

- Fill in the Default Part Cycle Time information.

- Save your changes.

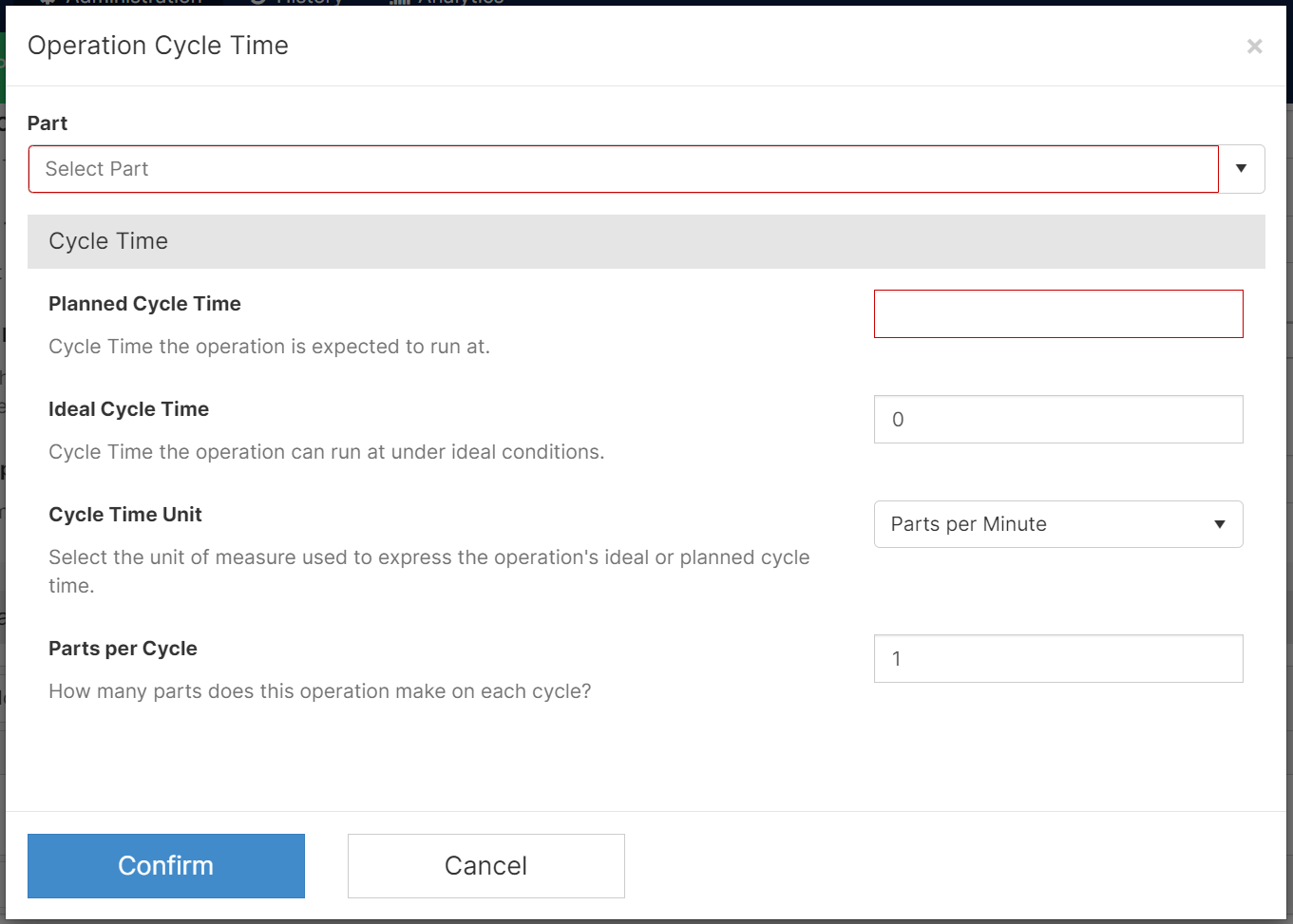

Operation Cycle Time

Cells/Machine

When a machine runs different part numbers at different cycle times, the Operation Cycle Time section helps you define them. The system will calculate the performance based on the established cycle time for the part.

- On the Administration Tab, click on Cells/Machines on the Hierarchy.

- Add a Machine or edit the machine you need.

- Select the Cycle Time Tab.

- Scroll down to the section Operation Cycle Time and click Add Operation Cycle Time.

- Part: This is required.

- Planned Cycle Time: This is required.

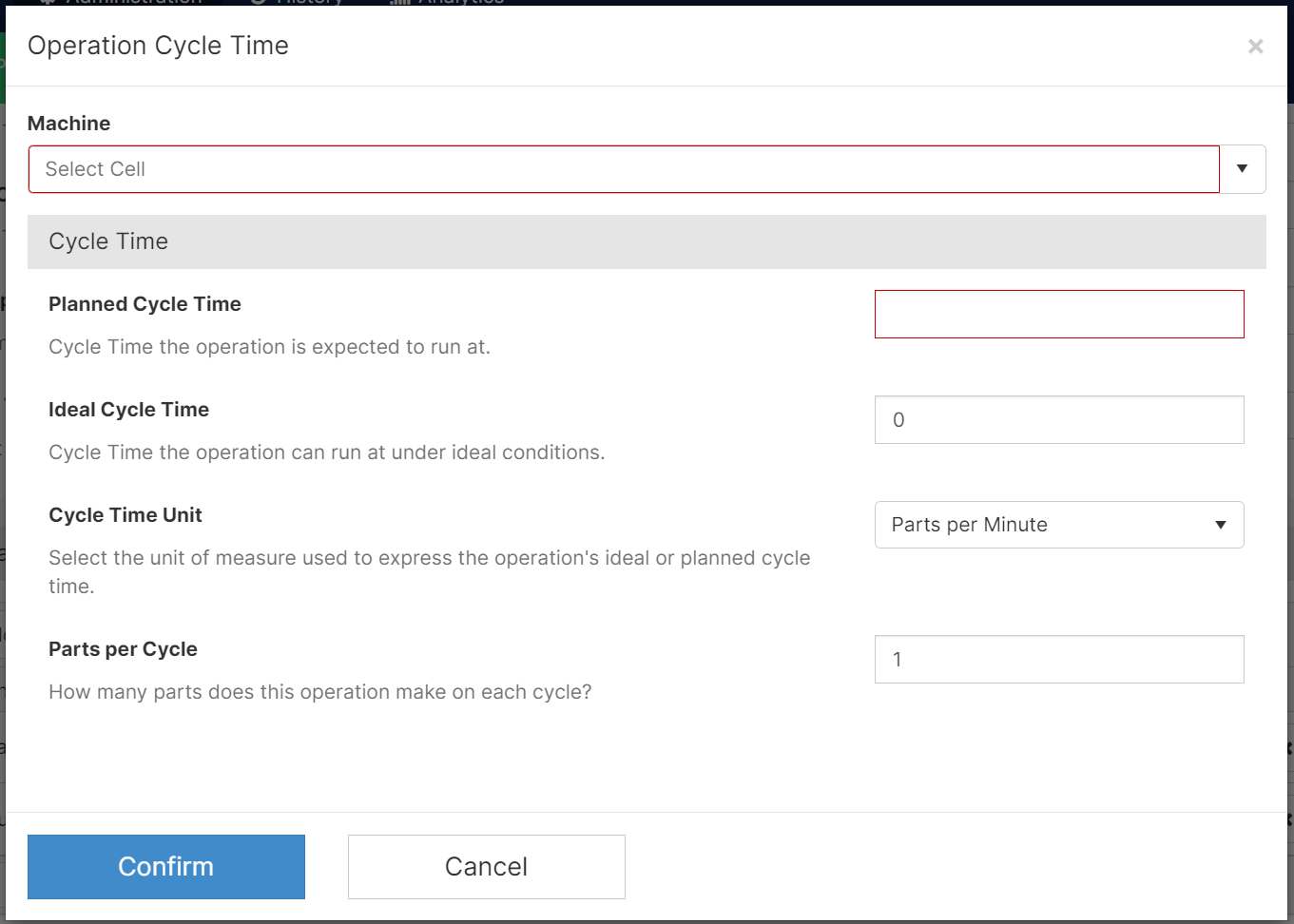

Parts

One part number can be manufactured in multiple machines. You can specify the part's cycle time per machine in the Operation Cycle Time section.

- On the Administration Tab, select Parts on Master Data.

- Add a Part or edit the part you need.

- Select the Cycle Time Tab.

- Scroll down to the section Operation Cycle Time and click Add Operation Cycle Time.

- Machine: This is required.

- Planned Cycle Time: This is required.