Details on how cycle times are calculated

Below are the definitions, formulas, and examples of how cycle times are calculated in Mingo.

Definitions

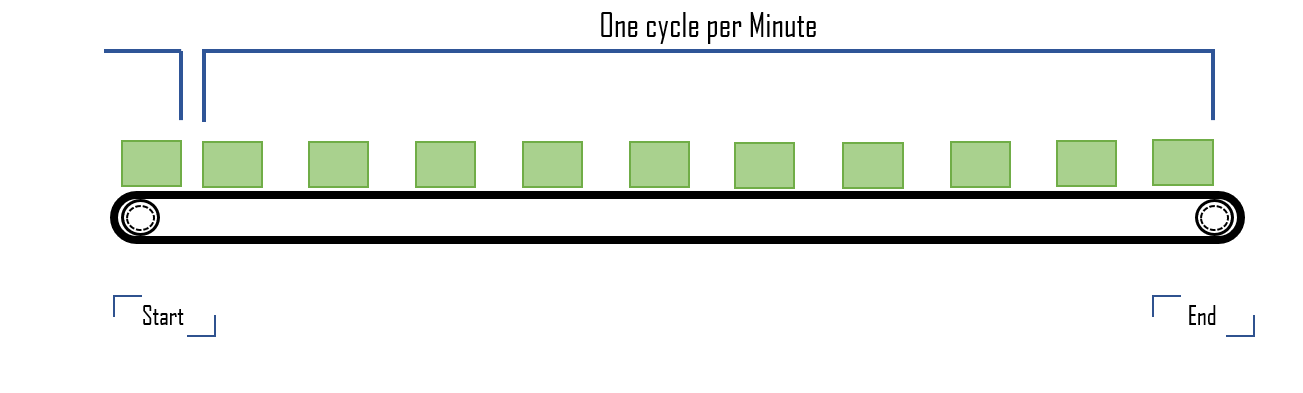

Actual Cycle Time: The rate at which a machine or process produces one or more parts expressed in cycles per minute (CPM). The machine is actually running at this cycle time metric.

Planned Cycle Time: Metric entered by the customer expressed in their preferred unit of measure. The cycle time the machine was expected to run at.

Ideal Cycle Time: It is the target cycle time. For example, a machine might have the capacity to run at 100 parts per minute. However, the plant is currently running at 80 parts per minute. The Ideal Cycle Time would be 100, and the Planned Cycle Time would be 80.

Cycle Time Unit: the preferred unit of measure used by the company to express their Cycle Time.

A list of Cycle Time Units can be found here.

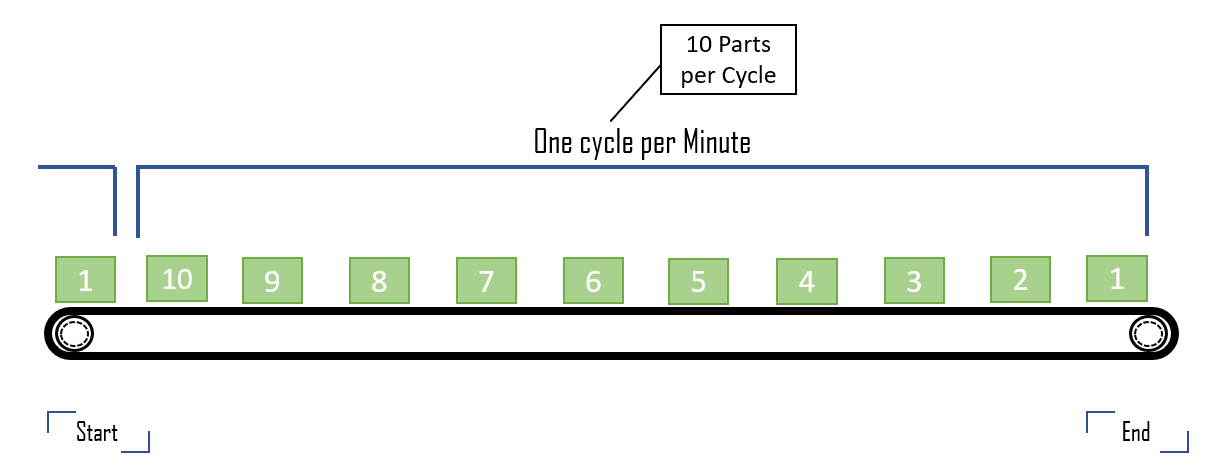

Parts per Cycle: the number of parts created per cycle. If the Parts per cycle are not defined, Mingo assumes one part per cycle.

Short Stop Threshold: the number of minutes that need to pass without seeing a part to trip a short stop downtime. This is either entered as a duration in minutes or a percentage of the Cycle Time. Please refer to the table below to see a representation of the percentages.

| Cycle Time (Minutes) | Percentage | Short Stop amount of minutes |

| 10 | 50 | 5 |

| 10 | 100 | 10 |

| 10 | 300 | 30 |

Operating Time: the total number of minutes the machine is in operation during a shift. This excludes both planned and unplanned downtime.

Target Total Quantity: the total number of parts expected to be produced within the Operating Time.

Total Quantity: the total number of good and scrap parts produced during the shift.

Formulas

Short Stop Threshold: (1 / Cycle Time) * Stop Threshold Percent

Target Total Quantity: Floor(Cycle Time * Operating Time) * Parts per Cycle

Performance: Total Quantity / Target Total Quantity

Examples

A company has a machine that produces 2 widgets every 80 seconds. They express their Cycle Time in 80 SPC and 2 Parts per Cycle, or (1 / 80 SPC) * 60 = 0.75 CPM.

The short stop threshold is set at 200% of Cycle Time. The Short Stop Threshold would be (1 / 0.75 CPM) * 200% = 2.67 minutes.

After 30 minutes of operation (no downtime), we would expect a Target Total Quantity of Floor(0.75 CPM * 30 minutes) * 2 Parts per Cycle = 44 parts.

And if they produced 40 parts during that hour, their Performance would be 40 parts / 44 Target Total Qty = 90.09%.