Track any data and correlate it with production runs.

Overview

Process data can be used to track all additional information that is not used to calculate OEE, but is still valuable for analysis. It is a great tool to track quality data.

Examples:

- Temperature

- Speed

- Feeds

- Pressure

- Flow Rates

- Humidity

You can choose which process metrics are collected on which machines or lines.

There are two ways to collect process data:

- Manually from the Operator Screen

- Automatically from sensors and machines

This feature is only available for Black Belt subscriptions

Security

To setup Process Data Metrics a user must have the Process Data Metrics entitlement turned on.

Setup

Automatic process data collection is available for any Black Belt. Manual process data collection must be enabled for your company. Reach out to your account manager to get this turned on.

To setup process data:

- Go to Administration on the navigation bar.

- Click on Process Data Metrics.

- Click Add Process Data Metric.

- Complete the fields, the descriptions are below.

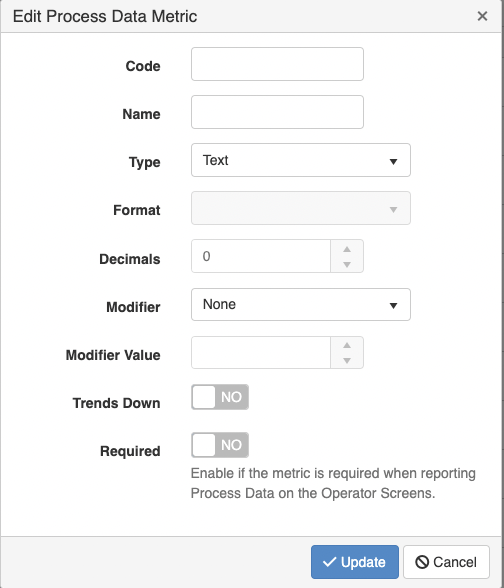

Field Descriptions

| Field Name | Description |

| Code | An internal code for this metric, does not have to be unique. |

| Name | Name of the process data metric |

| Type | Data type of the metric: Text, Number or Date |

| Decimals | Number of decimals when this number is displayed. |

| Modifier | If the data needs to be altered from the reported value you can add, subtract, multiply or divide the original value. The modified value will be used on dashboards. |

| Trends Down | Turn this on if a trend decreasing should be shown in green. For example, a downtime should decrease not increase, if this is turned on and downtime goes down the trend will be green. |

| Required | Require and entry for this metric. This is only applicable to manual process data collection. |

Manual Process Data Entry Setup

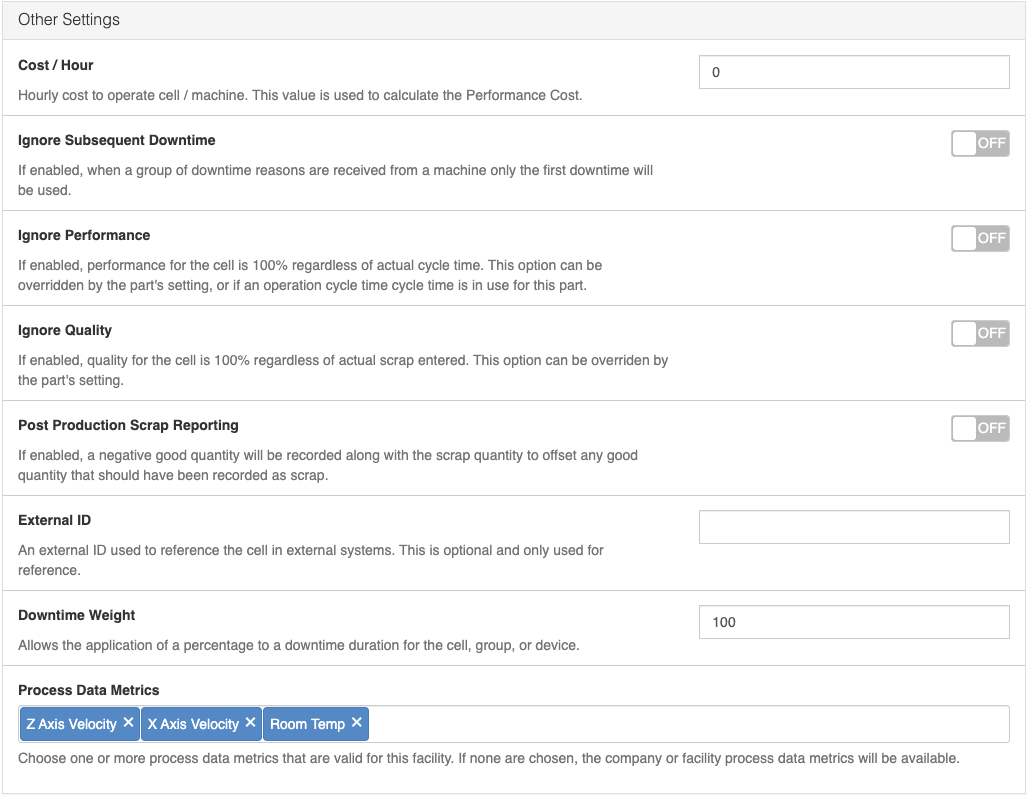

You can limit the process data metrics available on a machine or line by selecting them on the Settings tab of the Facility, Department, Cell/Machine or Station.

The settings follow the location hierarchy.

Manual Process Data Entry

To enter process data:

- Navigate to the Operator Screen for a specific machine or line.

- Click the process data button.

- Enter the process data.

- Click Submit.