The Operator Screen supports a keyboard-based barcode reader.

Summary

Mingo's Operator Screen supports the following operations with a barcode reader: Clock-In and Clock-Out, record a Quantity (just the quantity or paired with a serial number) or Scrap, start and stop a Downtime, change over a part, a job number, or a Work Order. An example of a reader would be the Zebra LS2208.

For more information, scroll down to the "How to Set Up Devices" Section.

Prefix Formats

| License Level | Actions | Prefix | Format | Example |

|

Lean |

Operator Clock-In and Clock-Out | ^O | ^O[Employee ID] | ^O1234 |

| Quantity | ^Q | ^Q | ||

| Scrap | ^S | ^S[Scrap Code] | ^SBREAK | |

| Start a Downtime | ^D | ^D[Downtime Code] | ^DOPERATORSTOP | |

| Stop a Downtime | ^D | ^D | ||

| Part Change Over | ^P | ^P[Part Number] | ^P10001 | |

| Job Number Change Over | ^J | ^J[Job Number] | ^JWO123 | |

| Black Belt | Work Order Change Over | ^W | ^W[Job Number] | ^WWO123 |

| Enterprise | Serial Number Barcode Sequence | ^QC | ^QC[cf_serial_number] | ^QC1234 |

Explanation of each Action

The actions on this list will be executed on the Operator Screen that is active. Before you scan a barcode, make sure you are on the right Operator Screen.

- Clock-In or Clock-Out

- Based on the current status, the scanner will Clock-In or Clock-Out the operator. For example, if a worker wants to clock in using a batch, the scanner will clock them in on the active operating screen.

- Record Quantity

- A single quantity will be reported for the part being produced.

- Record Scrap

- A single scrap quantity will be recorded for the scrap code associated with the barcode and the part being produced.

- Start a Downtime

- A downtime timer will begin with the Downtime Code connected to the barcode.

- Stop a Downtime

- A downtime event will stop if ^D is scanned.

- Part Change Over

- The currently produced part will change to the part associated with the Part Number in the barcode.

- Job Number Change Over

- The machine will change over to the job number in the barcode; however, the Part will remain the same.

- Work Order Change Over

- The machine will change over to the Work Order associated with the barcode.

- Serial Number Barcode Sequence

- A custom field must exist on the Events Object. This custom field label should be serial number, and the field should be cf_serial_number.

- A quantity of 1 will be recorded with the serial number. For example, ^QC123 creates a quantity of 1 with Serial Number 123.

How to Set Up Devices

Zebra LS2208

For the Zebra LS2208, the application you need to add the prefixes is 123Scan.

Scan One Action

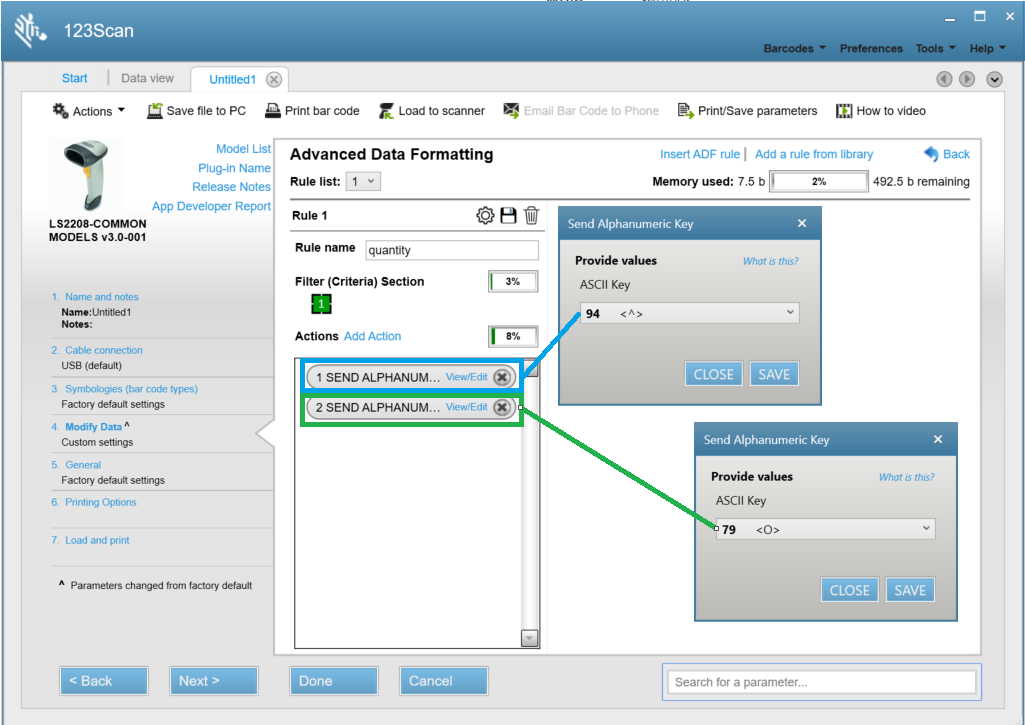

If you are using the scanner for one action, then it is recommended to integrate the prefixes into the scanner. An example would be clocking-in and clocking-out an operator. Go to the 123Scan app and add an ADF (Advanced Data Formatting) action to send an alphanumeric key with each scan. It looks something like this:

Scan Multiple Actions

If you are using the scanner for more than two actions, then it is recommended to integrate the letter prefix format into the barcodes. For example, if you want the scanner to change job numbers and work orders:

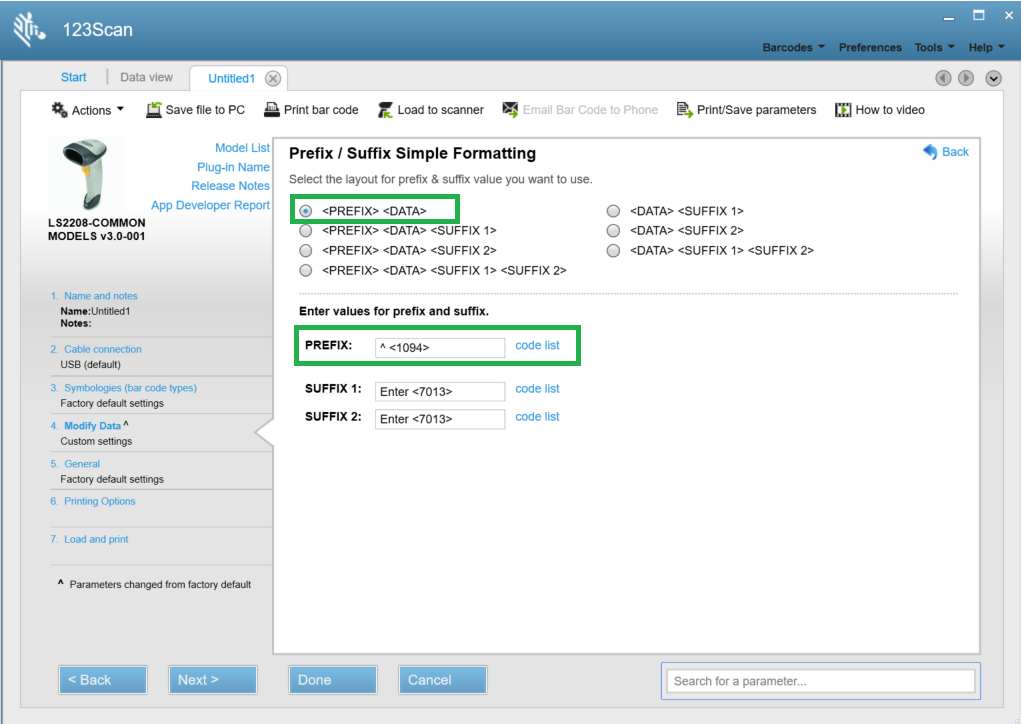

Using the 123Scanner, add the "^" prefix to the scanner by adding a basic complex data modification.

Additional Information

rf IDEAS: Wave ID Solo

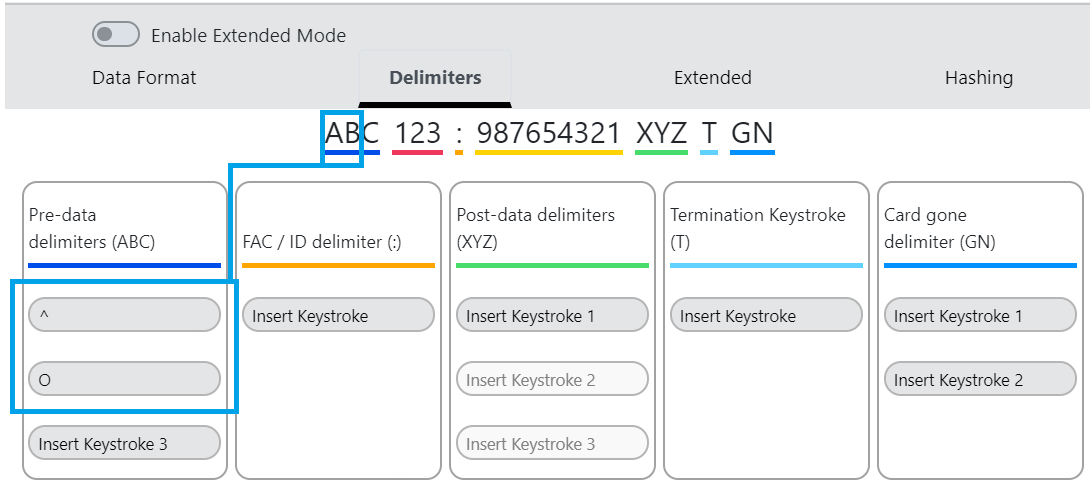

The Wave ID Solo is a card reader. Customers use this card reader to clock-in and clock-out operators. On the rf IDEAS program, go to the Delimiter Tab on the Format Tab.

Add the Delimiter or Prefix to the data to clock in and out an Operator.

Additional Information